Hand Router

My first project is a skill builder exercise using a hand router to cut a particular shape out of a piece of wood. Ben said we could make any shape we wanted, but I elected to replicate the shape outlined in the exercise description.

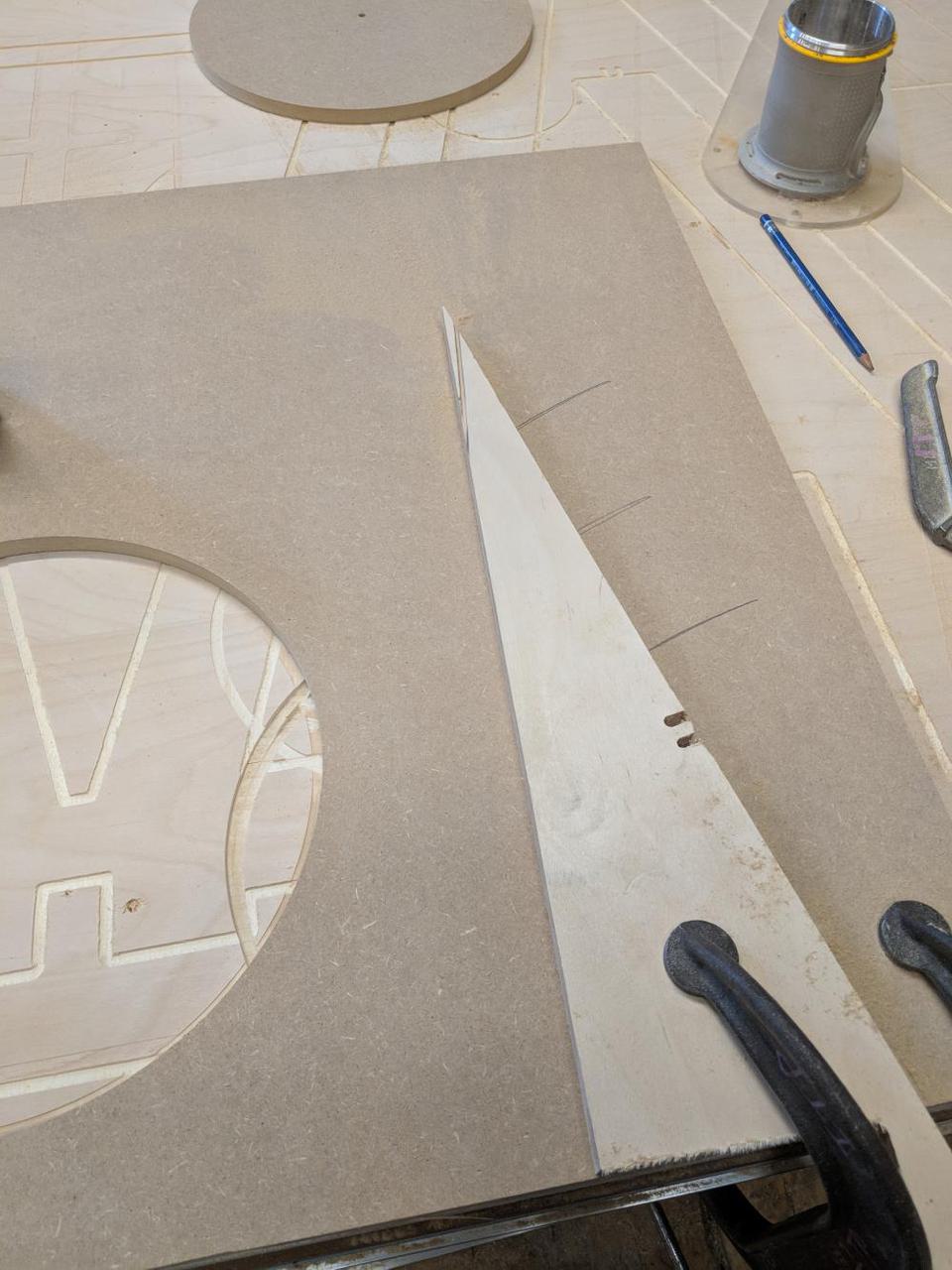

Here is the end result:

I encountered some problems making this that I will describe below.

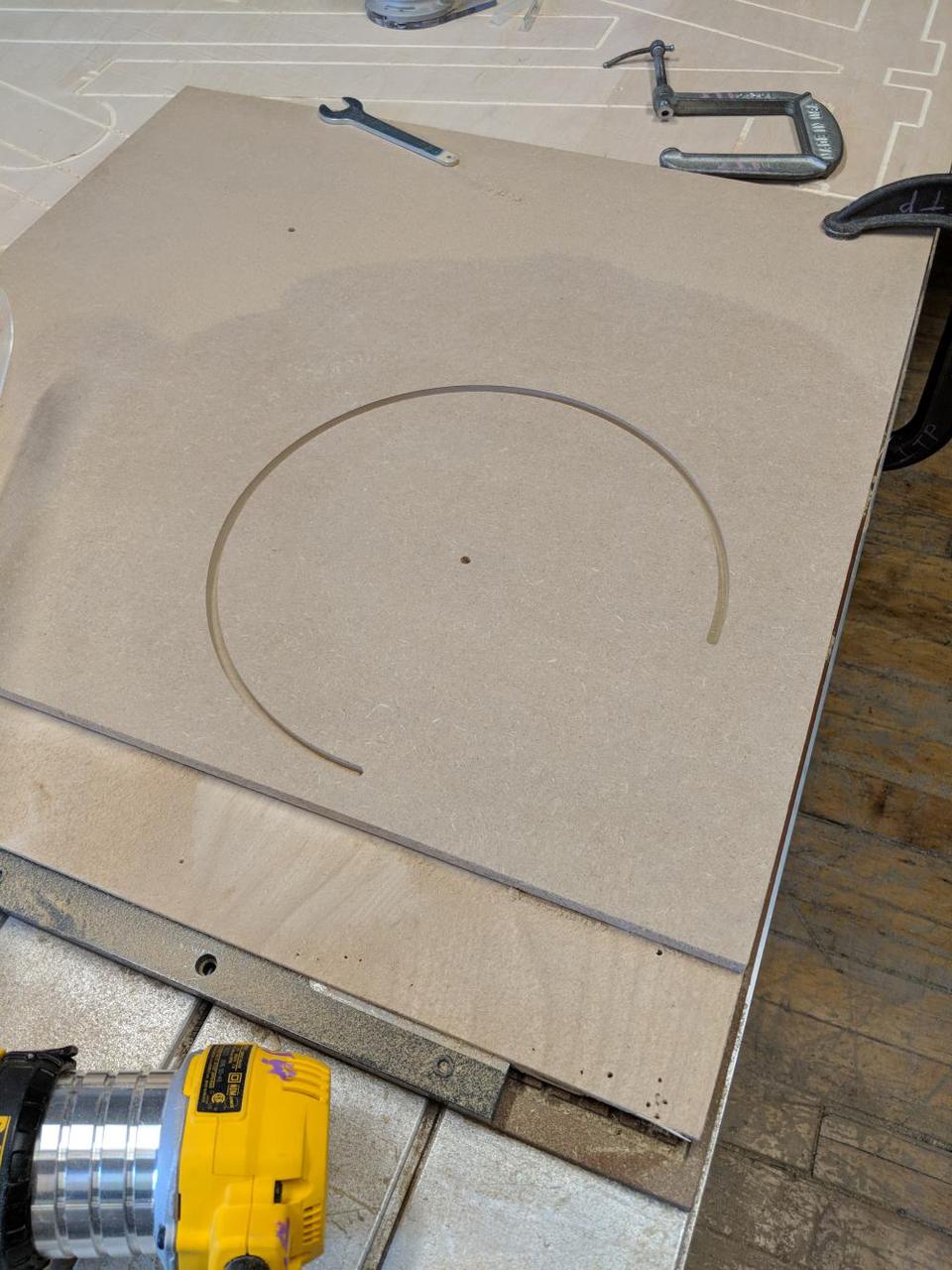

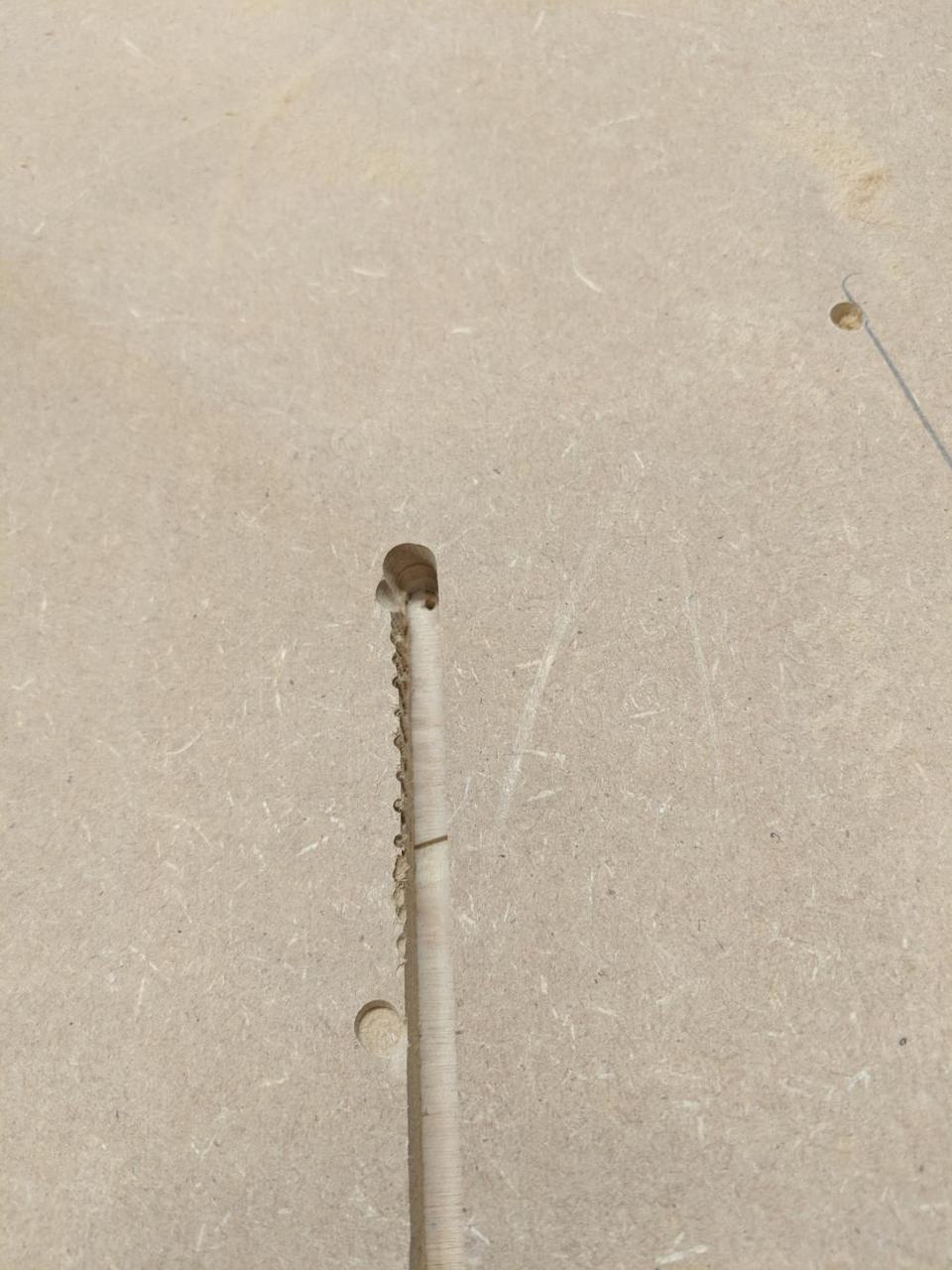

Here's where I started. I drilled a quarter inch hole into the wood and inserted a wooden peg for the circle jig to revolve around. The router goes around the arc clockwise.

One problem is I didn't make measurements and mark the wood to indicate where I should start and stop the arc. Sometimes I would make a mistake and end my router pass too soon or go farther than previous passes. I could manage this by carefully observing the router bit position.

There was a lot of sawdust. After covering myself in it I put on a shop apron but even that wasn't enough. Happily I could use the shop vacuum cleaner to vacuum the sawdust off myself in addition to vacuuming the sawdust from everywhere else. The accumulated sawdust in the groove made it difficult for me to gauge my progress. I had to frequently vacuum that out to assess if I needed to make more passes.

After completing the arc I cut a straight line. I used a scrap piece of wood to serve as a guide for the router.

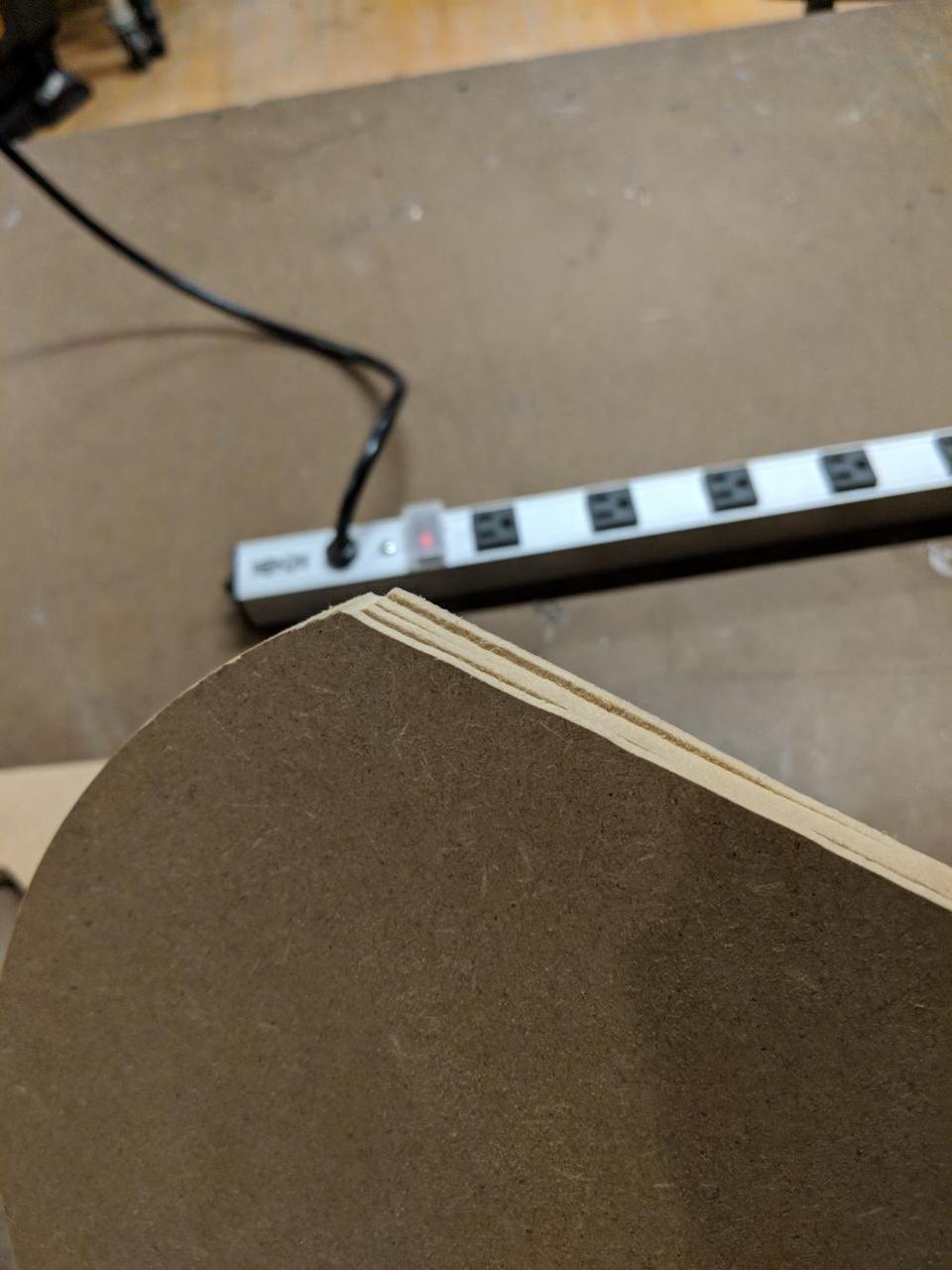

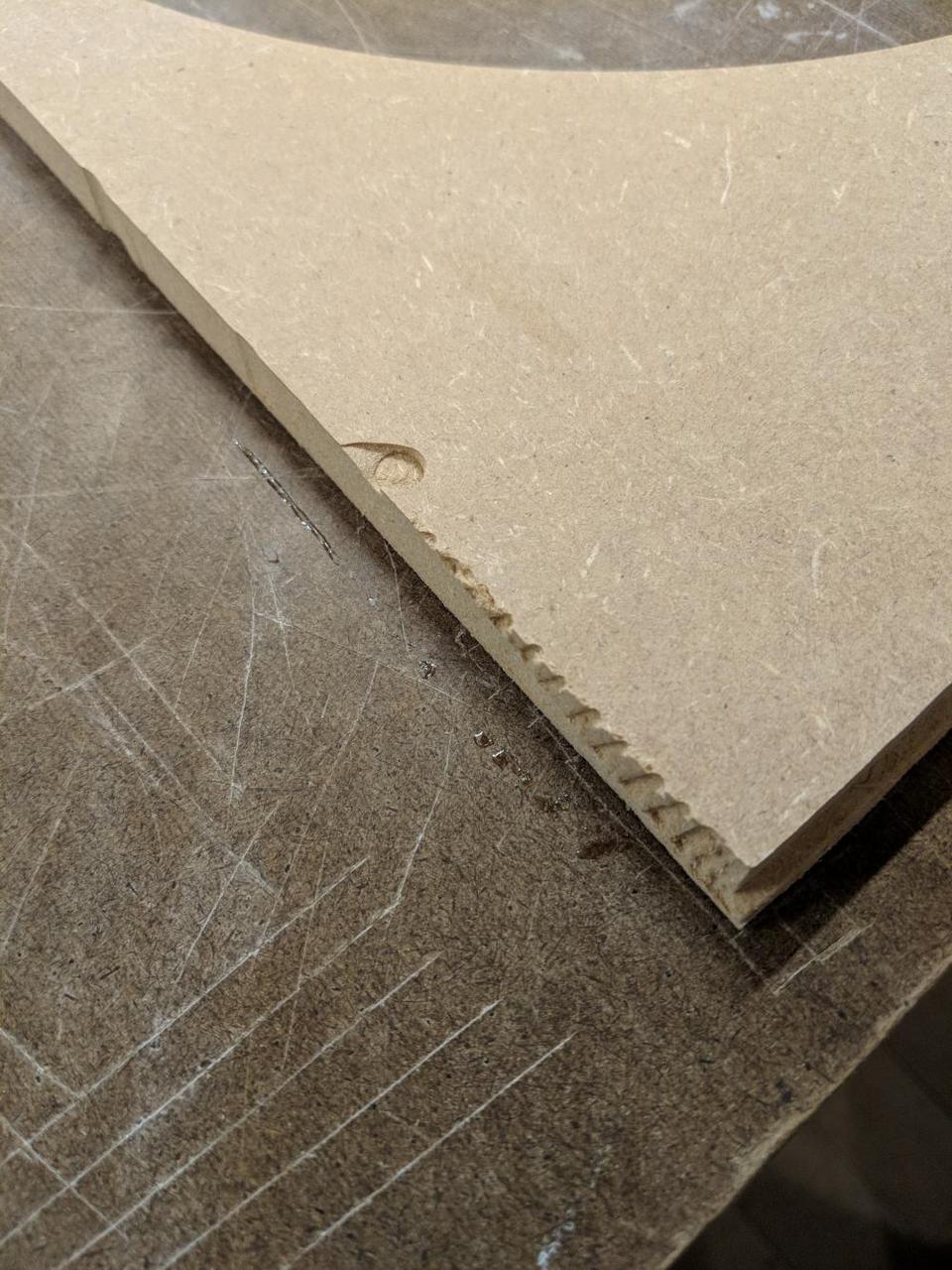

One problem I encountered here is the piece of wood moved slightly without me noticing. That caused some stratification in the cut, pictured below in the final result:

I also went slightly too far on one side:

One question I have here is why it matters which direction I move the router when cutting this straight line. The router seemed to be more manageable when I moved it away from myself, in the direction of a clockwise turn around the arc. Was I imagining this? Ben specifically mentioned this in class but I don't understand why it would matter when cutting a straight line. The line doesn't know where it is on the board or where it is in relation to the previous cuts.

Finally, the outside edge. I used the same piece of wood to guide the router. This time I marked where wood guide should go with a pencil. This would make it obvious if the wood moved again.

While cutting the first edge line I made a mistake with the router. The hand router seems to be best operated by people with four hands. The on-off switch is difficult to use and while fumbling with it I accidentally dug into the wood in an ugly and haphazard way.

I finished the second edge without incident.

I still managed to botch the cutting. The wood must have moved without me noticing.

And here's another closeup of the ugly mistake:

The hardest part of this exercise was dealing with the clamps. I spent a lot of time clamping and re-clamping things, often not successfully. Poor clamping caused many of my mistakes. I also could have made things easier on myself by making some measurements. It seemed like precision wasn't important here but I now see that it probably would have been faster to complete this with the extra effort.

I am happy to have learned this new tool but perhaps the most important lesson here is appreciate the precision and discipline offered by the CNC machine. I am eager to learn more about this in the coming weeks.

Comments