Wooden Box

For my Subtraction final I made this decorative box:

Every time I look at it I'm amazed I made it.

The reddish-orange wood comes from a Padauk (pah-DUKE) tree commonly found in Africa. It also goes by the name Vermillion.

For my Subtraction final I made this decorative box:

Every time I look at it I'm amazed I made it.

The reddish-orange wood comes from a Padauk (pah-DUKE) tree commonly found in Africa. It also goes by the name Vermillion.

This week's assignment is the Four-Axis Mill skill builder. Our goal was to get some experience using the machine.

I milled this simple object out of a dowel rod that was left over from a previous assignment.

Not everything went as expected. I did learn a lot about the limits of the machine though, and that makes me happy.

My next project is to build a wooden mallet with the lathe. It was quite a challenge! I look at this mallet and am amazed I was able to make this. The wood lathe is an intimidating machine.

In the second half of the class we will learn about the wood lathe. The lathe has been around for over 3000 years, first invented by the ancient Egyptians. The device would be operated by 2 people with one person turning the wood with a rope. These days the rotation is powered by a motor.

I was feeling nervous about this skill builder so I watched some instructional videos on YouTube. This one was my favorite:

She's my hero.

For my midterm project I created this towel rack for my apartment:

This is a double towel rack with 1 1/8" diameter bars for the towels. I specifically wanted thicker bars because I thought it would help keep the two sides of the towel from touching each other, facilitating drying. It also happens that the only place in my bathroom where I could possibly put a towel rack is in a location between the shower and the door that is a little bit less than 25" wide. Most towel racks I could buy at the store with 24" bars are too wide to fit in that space. Towel racks with 18" bars are too small for my towels. My current towel rack is a cheap wooden towel rack with a 24" bar that I bought at the store that I trimmed to be slightly shorter using the sander in the shop. I'm excited to soon replace it with this one.

My midterm project is going to be a CNC'ed towel rack. Last week I did some experimenting with CNC'ed joints so I could learn about the proper tolerances for the joints suitable in my design. This week I bought materials and did some test cuts. I wanted to know what sized hole would be best for the towel rod. I also wanted to see what sized hole would be best for the wooden screw hole buttons I bought. I'll need those to cover up the screws used to attach the towel rack to the wall.

The procedure is simple: make a bunch of holes with slightly different diameters and test them out. The experiment was a success. I'll incorporate these results into the design and will CNC the final product later this week.

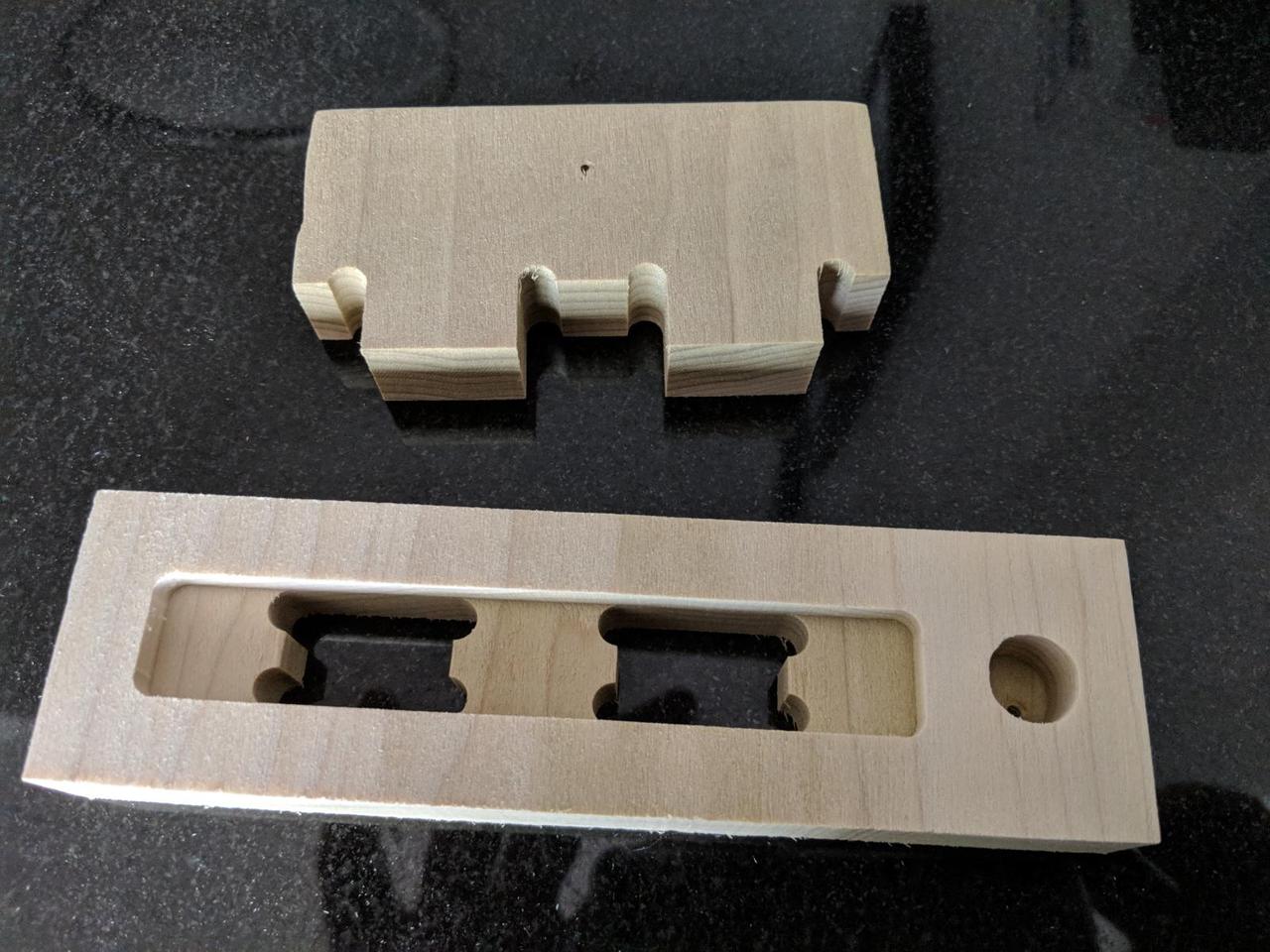

Our second CNC assignment is to create a wooden joint. We needed to mill the wood carefully so the result provides a solid connection between the two pieces.

I designed and milled a Blind finger tenon joint. I am pleased with the final result:

Our next machine is the CNC. CNC stands for Computer Networked Control, and works kind of like the Hand Router except it is controlled by a computer and not my hands. Our assignment was to build something with this using 'pockets' and 'contours'. The computer aided machining (CAM) software calls a carved out hole a 'pocket' and a cut line a 'contour'.

This was a challenging task. I had to go back and forth between the shop's CAM station and the CNC several times. The first trip back was because I forgot to set the depth levels to a negative number. Without that the CNC will mill the air above my wood. After I got that corrected I had some difficulty setting up the machine. John and Shreiya helped me turn the machine on and attach my wood to the CNC bed.

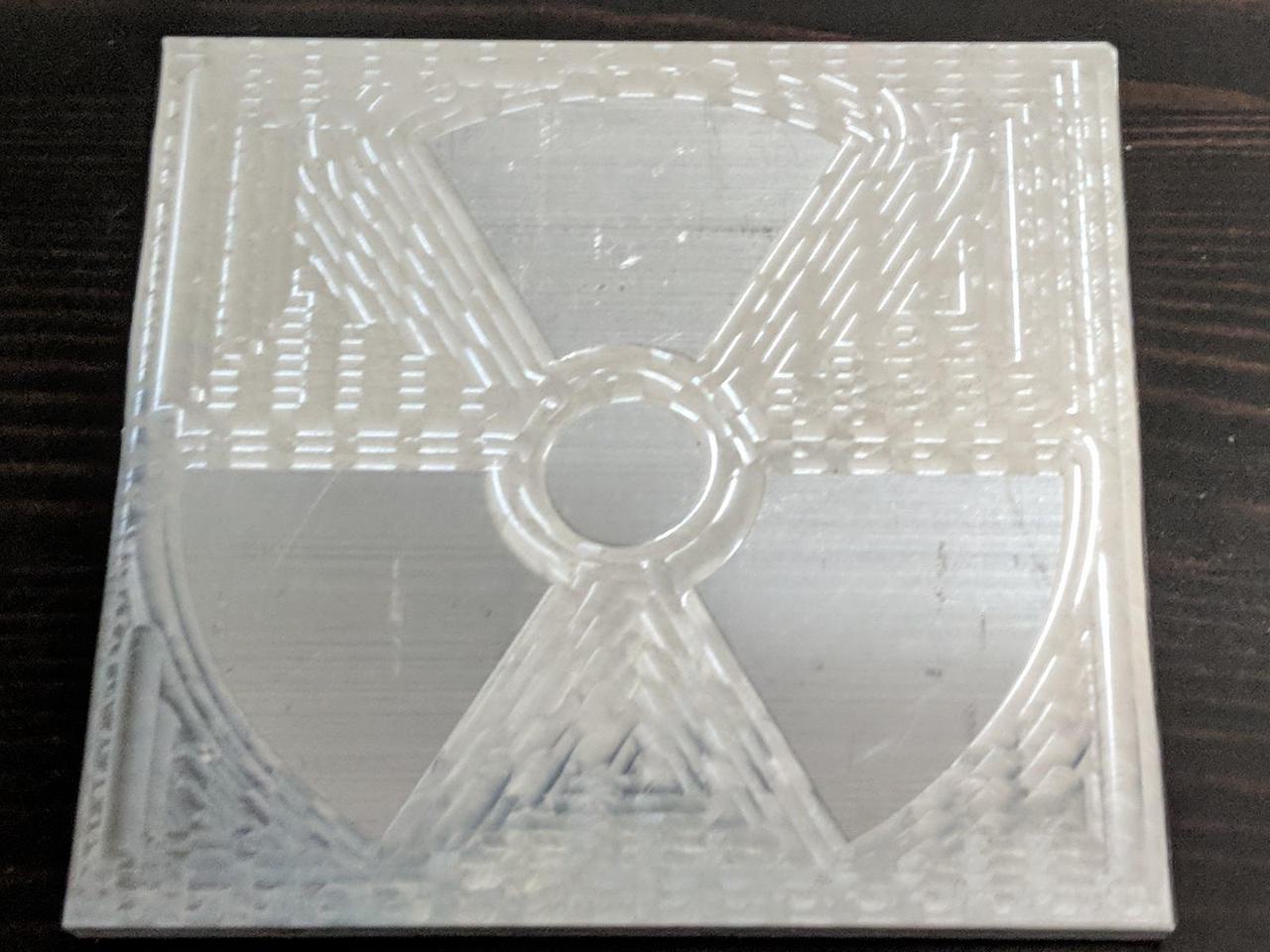

This week I milled aluminum with the Othermill. Here is the result:

I really like the Othermill.

Our second project is another skill builder exercise using the Othermill. Our goal was to get some experience using an Othermill to mill a piece of plywood. I created this simple object: